Transporting H-beams weighing hundreds of kilograms between workstations, whether by crane or forklift, presents significant challenges. Operators must not only carefully monitor the beams but also ensure the safety of personnel and equipment along the transport path. It’s a task fraught with complexity, but now there are more efficient solutions available.

One practical option is to utilize plain roller racks, which allow operators to manually move the beam back and forth with minimal effort. For more advanced handling requirements, motorized roller racks with integrated lifting mechanisms offer enhanced precision. With simple button controls, operators can direct beam movements or even feed the beams directly onto a working table with ease.

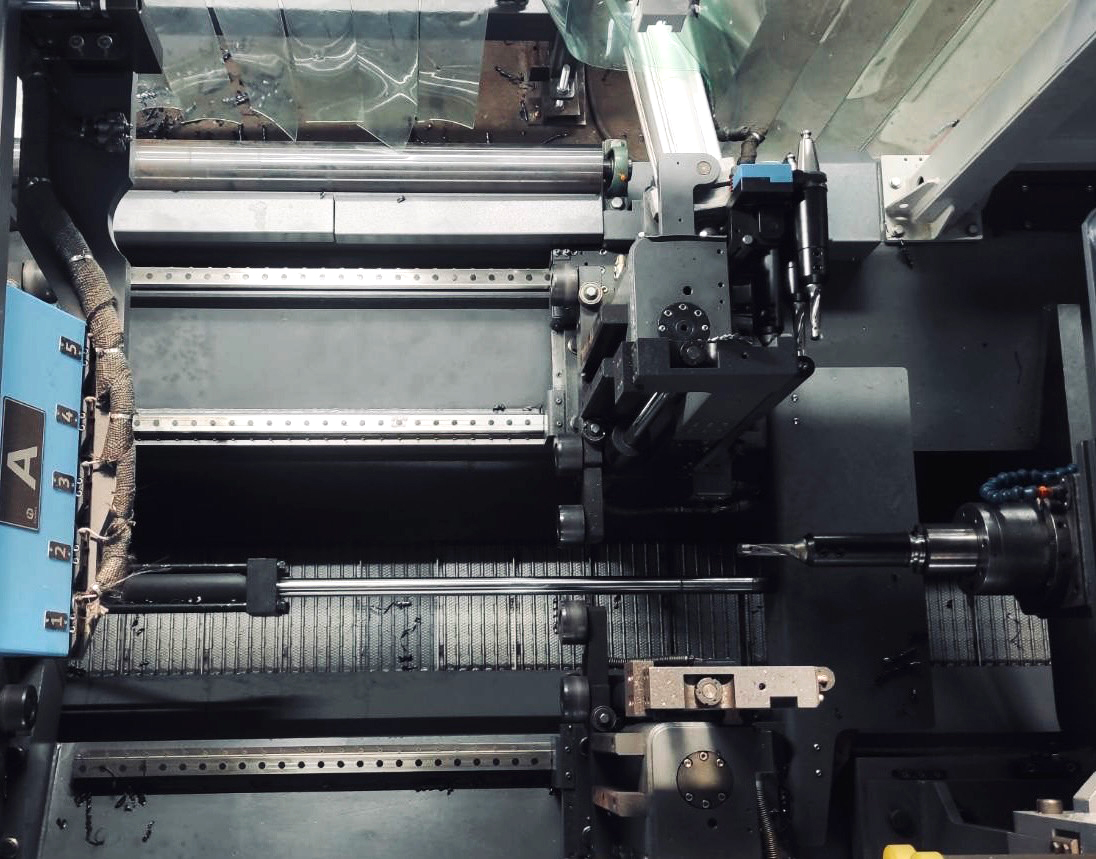

For those seeking maximum efficiency, a motorized roller conveyor system equipped with a feeding arm and buffer zone provides an ideal solution. This system enables the staging of multiple beams in the buffer zone, allowing the GD-SFM system to automatically manage loading and unloading operations. This automation significantly reduces manual labor requirements and optimizes overall productivity.

Contact us today to schedule a consultation. Our team will arrange a visit at your earliest convenience to discuss how these solutions can enhance your operational efficiency.