Marking on H-beams is a crucial process in the steel fabrication industry, providing precise guidelines for welding and installation to ensure a seamless and accurate workflow. Traditionally, manual marking methods using chalk or handheld engravers were common but often inefficient and prone to human errors.

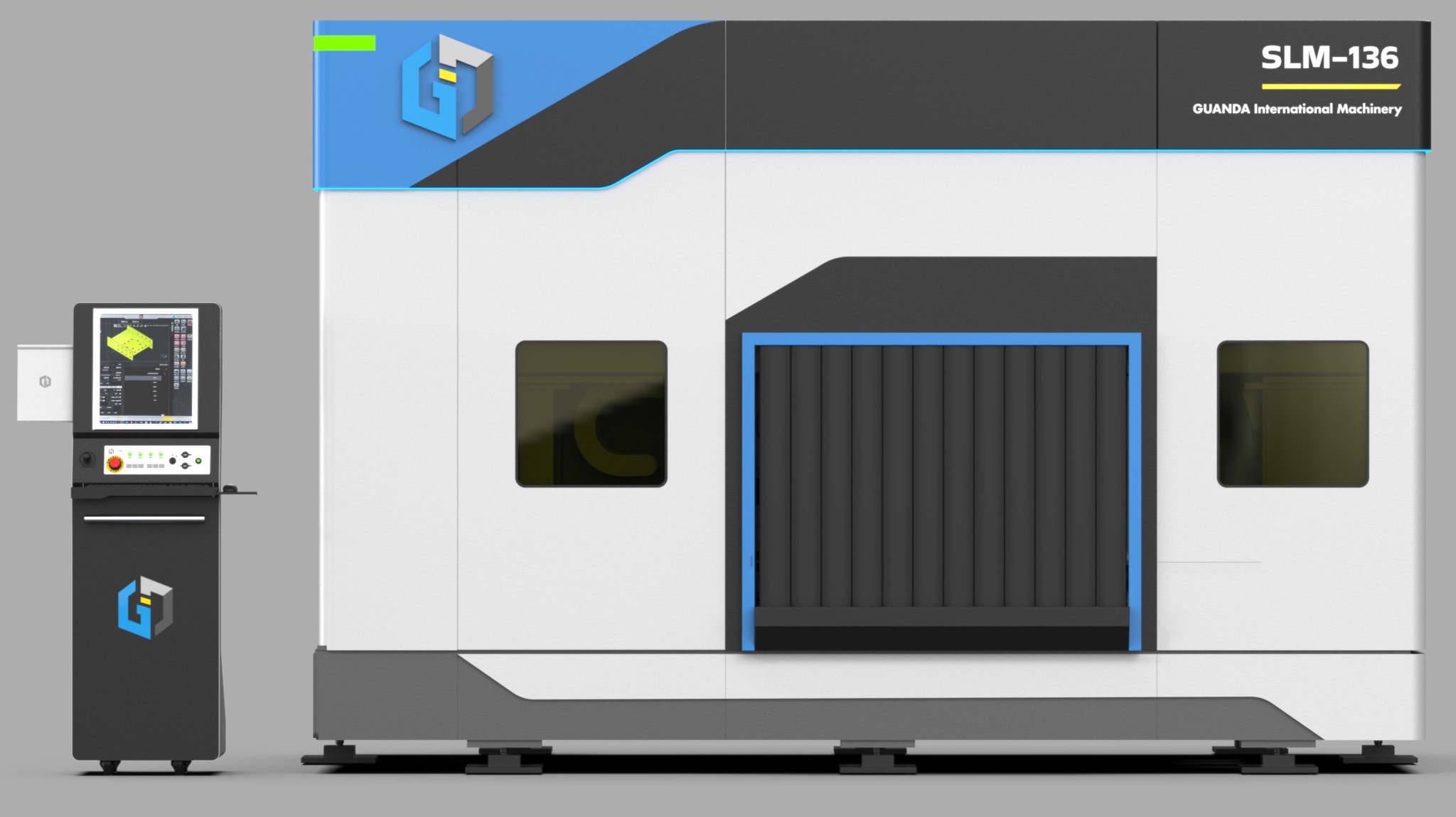

As the industry progressed towards automation, CNC beam drilling machines and automatic drilling machines began to take over the marking tasks, reducing labor costs and improving accuracy. However, as the demand for higher efficiency and precision continues to grow, GDM is introducing a new solution—the GD-SLM automatic laser marking machine.

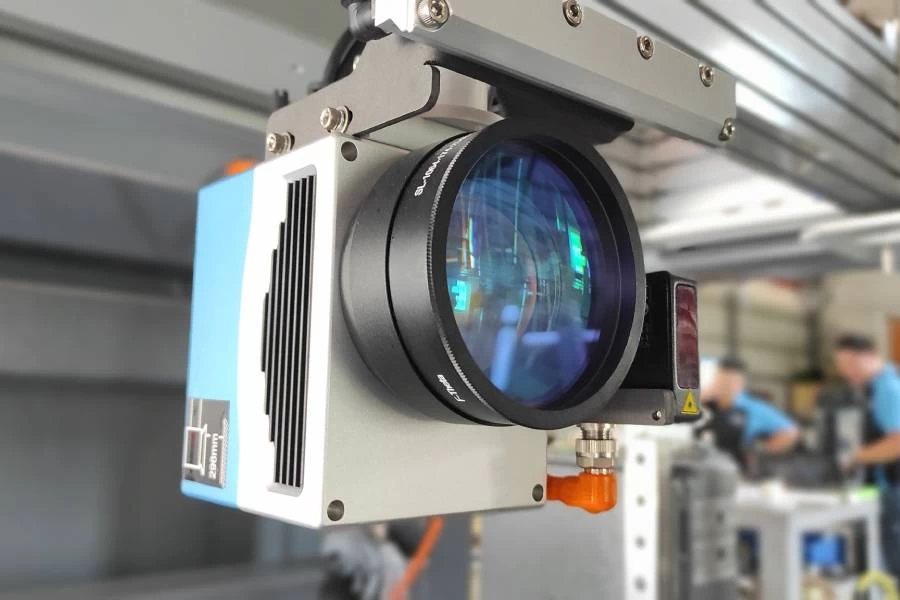

This advanced machine is equipped with four 100W laser heads, capable of marking the top, bottom, left, and right sides of H-beams simultaneously, enabling full-coverage marking. Compared to traditional methods, the GD-SLM offers higher precision and eliminates the need for consumables, significantly reducing operating costs.

In addition, the GD-SLM seamlessly integrates with GD-AutoMate, an automated material handling system, enabling automated loading and unloading operations. This integration enhances overall productivity and ensures a smooth and efficient workflow, maximizing the synergy of an automated production line.

The GD-SLM operates on the highly acclaimed GD-SFM system, which has proven its success in the GD-STD 3-Axis Drilling Machine. The software allows for seamless data transfer from TEKLA Structures Software, eliminating the need for on-site programming and greatly reducing the operational burden. This provides a more convenient and intuitive user experience.

Contact us today to schedule your visit. Our dedicated sales and engineering teams will arrange a comprehensive demonstration for you, offering in-depth insights into our innovative technology and tailored solutions to meet your production needs.